How we can help…

C & S Machine and Manufacturing Corporation is the single-source manufacturer for all your CNC machining and full-service metal fabricating needs. Our world-class production facility specializes in precision CNC machining, full-service metal fabricating, and rapid response capabilities; allowing us to offer quick turnarounds on quantities from one to 10,000+ at the most competitive costs when our customers need us most.

We stock an array of raw materials allowing us to provide fast-response, on-demand services to our clients ensuring our capability of providing unmatched customer service for jobs of any size. From the simplest jobs to the most complex, C & S has what it takes to meet your needs.

Examples of Our Technology

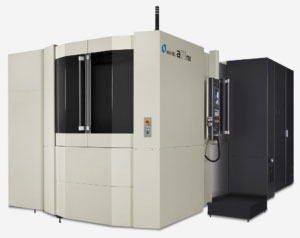

MAKINO A71NX

This machine’s stiffness and rigidity can tackle a wide variety of ferrous, non-ferrous and hard metal applications. The direct drive NC rotary table provides some of the fastest chip to chip times on the market.

OKUMA LB3000

This machine delivers high-quality machining from heavy to high-speed cutting. The live tooling, sub-spindle, and Y-axis features allow us to minimize work holding and work ops.

DOOSAN PUMA V550

This high-precision vertical turning center features large turning capacities and can handle heavy stock up to 18” in diameter. The sturdy rib structure provides excellent vibration absorption.

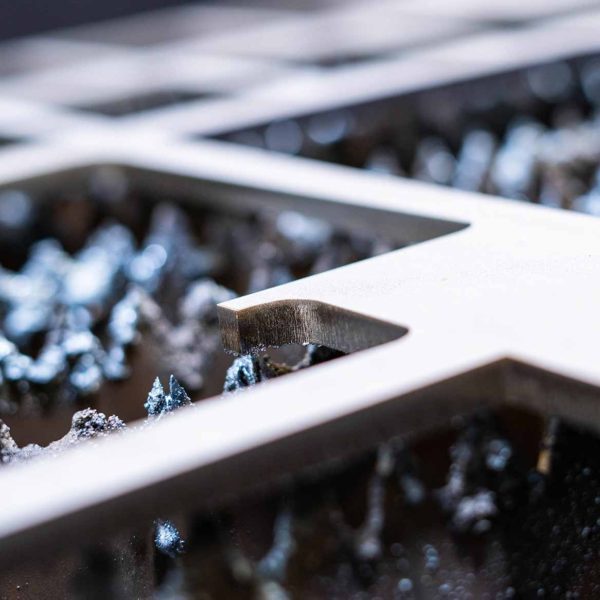

AMADA ENSIS 3015 AJ

This machine utilizes a highly innovative resonator to automatically adjust the diameter of the beam which allows operators to process a variety of materials at greater speeds compared to a CO2 system. The fiber laser can cut mild and stainless steel, aluminum brass, copper and titanium.

AMADA 8025 NT

A wide variety of part geometries can be accurately processed thanks to a high-precision tapered backgauge. To provide maximum productivity, the HD’s intelligent control digitizes the bending process and delivers highly efficient offline programming.

LINCOLN ELECTRIC SYSTEM 35

This weld cell is designed with dual fixed tables. One table can be loaded and unloaded while parts are being welded on the other. The workcell is outfitted with FANUC ArcTool software and a PowerWave power source.